push fit pneumatic connections

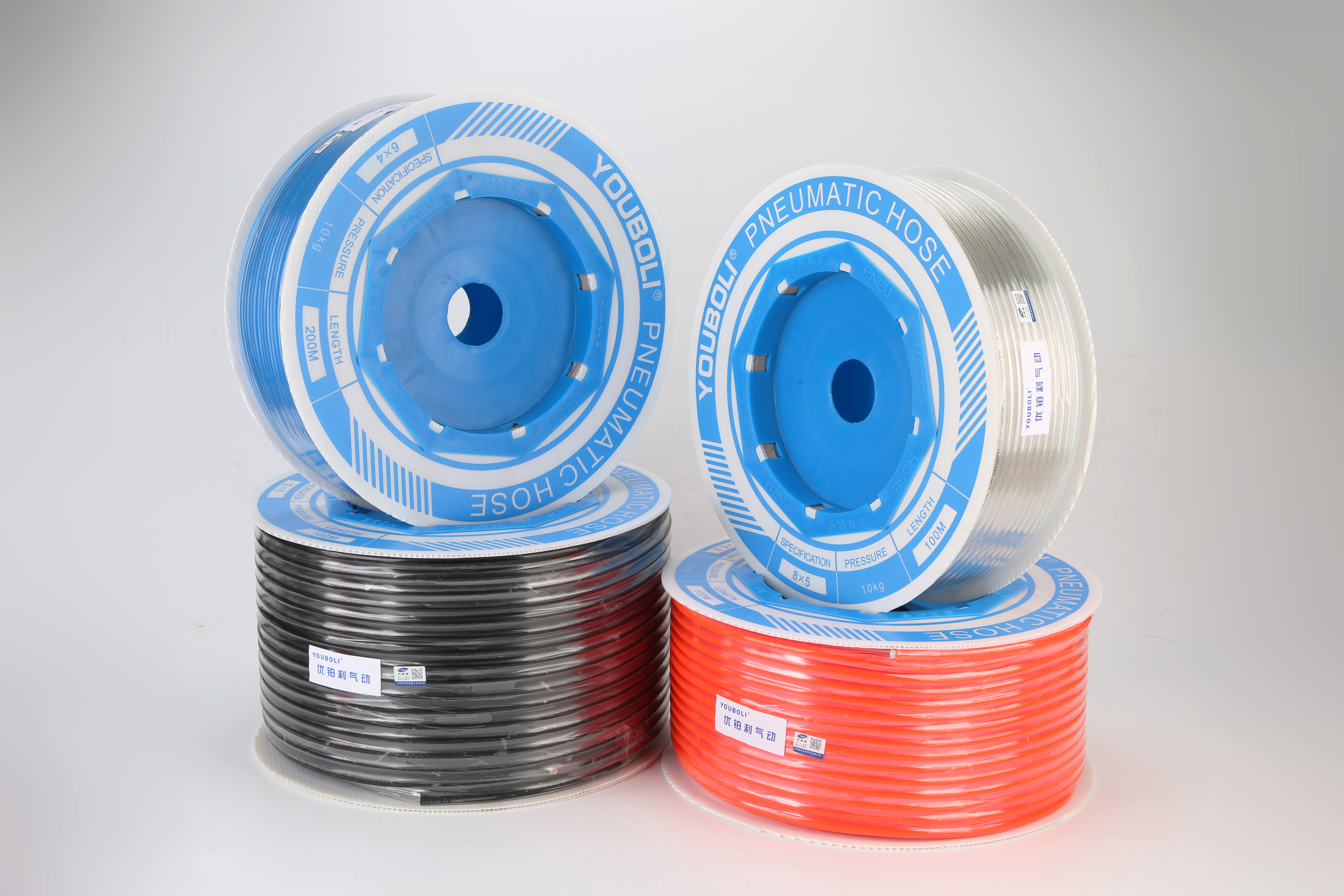

Push fit pneumatic connections represent a revolutionary advancement in fluid and air system connectivity, offering a streamlined solution for various industrial and commercial applications. These innovative connectors utilize a precise mechanical design that allows for quick, secure connections without the need for specialized tools or complex installation procedures. The system works through a unique collet mechanism that automatically grips the tube when inserted and creates a reliable seal, while an internal O-ring ensures leak-free operation under pressure. The technology incorporates advanced materials, including high-grade engineered polymers and corrosion-resistant metals, making them suitable for diverse environmental conditions. These connections are designed to handle various pressure ranges and are compatible with multiple tube materials, including nylon, polyurethane, and other common pneumatic lines. The versatility of push fit connections extends across numerous industries, from manufacturing and automotive to food processing and medical equipment, where they provide consistent performance and reliability. Their design accommodates both metric and imperial sizing standards, ensuring global compatibility and ease of integration into existing systems.