Choosing the right size of an air Cylinder is crucial for smooth operations. If you choose the right size, you can avoid equipment damage or costly downtime. A systematic approach helps you avoid these issues. It ensures the cylinder delivers the performance and safety you need for your specific Application.

Key Factors to Choose the Right Size

When you’re trying to choose the right size of an air cylinder, several factors come into play. Let’s break them down so you can make an informed decision.

Load Requirements

Start by understanding the load your air cylinder needs to move. This includes the weight of the object and any additional forces, like friction or gravity, that might affect movement. If you underestimate the load, the cylinder won’t perform as expected. On the other hand, oversizing it can waste energy and increase costs. Always aim for a balance that matches your application.

Stroke Length

The stroke length refers to how far the cylinder’s rod needs to extend or retract. Measure the distance your application requires and add a little extra for safety. A cylinder with too short a stroke won’t complete the task, while one that’s too long may not fit your space. Precision here is key.

Speed and Cycle Time

How fast does the cylinder need to operate? Speed and cycle time depend on your application’s demands. Faster speeds may require larger bore sizes to maintain force. Keep in mind that higher speeds can also increase wear and tear, so choose wisely.

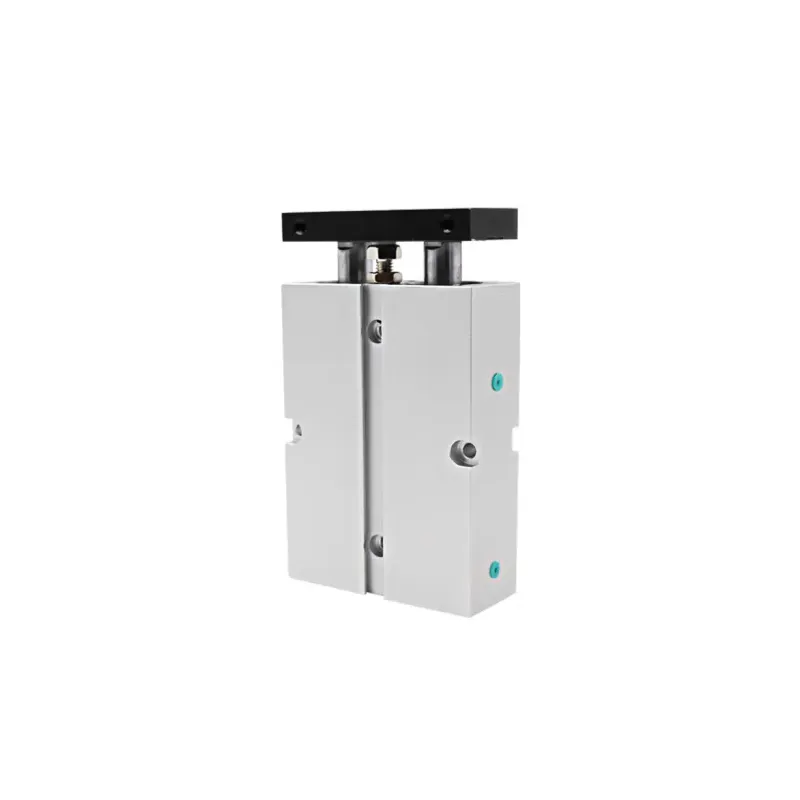

Mounting Options and Space Constraints

Finally, consider where and how the cylinder will be mounted. Look at the available space and the type of mounting required. Compact spaces may need smaller cylinders or special mounting brackets. Always double-check dimensions to avoid installation headaches.

By keeping these factors in mind, you’ll be better equipped to choose the right size of air cylinder for your needs.

Step-by-Step Guide to Choose the Right Size

Choosing the right air cylinder size doesn’t have to feel overwhelming. Follow these steps to make the process easier and ensure your cylinder fits your application perfectly.

Define the Stroke Length

Next, measure the distance the cylinder’s rod needs to travel. Add a little extra to account for any misalignments or adjustments. This ensures the cylinder can complete its task without running out of reach.

Select the Rod Diameter

The rod diameter affects the cylinder’s strength and stability. A thicker rod can handle heavier loads but takes up more space. Match the rod size to your load and mounting setup for the best results.

Calculate the Cylinder Speed

Finally, determine how fast the cylinder needs to move. Speed depends on the air supply and bore size. If your application requires quick movements, make sure your air supply can keep up. Otherwise, you might experience delays or inconsistent performance.

By following these steps, you’ll be able to choose the right size of air cylinder with confidence. Each step builds on the last, so take your time and double-check your calculations.

Common Mistakes to Avoid

Even with the best intentions, it’s easy to make mistakes when selecting an air cylinder. Let’s go over some common pitfalls so you can avoid them and make the best choice for your application.

Ignoring Friction and Load Variations

One of the biggest mistakes is forgetting to account for friction and load changes. Friction can come from guides, seals, or the surface the load moves on. If you don’t factor this in, your cylinder might not generate enough force to move the load. Load variations, like sudden weight changes, can also throw off your calculations. Always add a buffer to your force requirements to handle these variables. It’s better to be prepared than to deal with performance issues later.

Overlooking Safety Margins

Skipping safety margins is another common error. You might think you’ve calculated everything perfectly, but real-world conditions can be unpredictable. Without a safety margin, your cylinder could fail under unexpected stress. A good rule of thumb is to add 25-50% more force than your calculations suggest. This extra capacity ensures your cylinder operates reliably, even in challenging situations.

Disregarding Stroke Length and Space Limitations

Not considering stroke length and available space can lead to installation headaches. If the cylinder’s stroke is too short, it won’t complete the task. If it’s too long, it might not fit in the designated area. Measure carefully and double-check your dimensions. Also, think about how the cylinder will move within the space. Planning ahead saves you from costly adjustments later.

By avoiding these mistakes, you’ll be better equipped to choose the right size of air cylinder for your needs. A little extra attention now can save you time, money, and frustration down the road.

Choosing the right air cylinder size doesn’t have to be complicated. By focusing on load, stroke length, speed, and pressure, you’ll make smarter decisions. A systematic approach helps you avoid costly mistakes and ensures reliable performance.