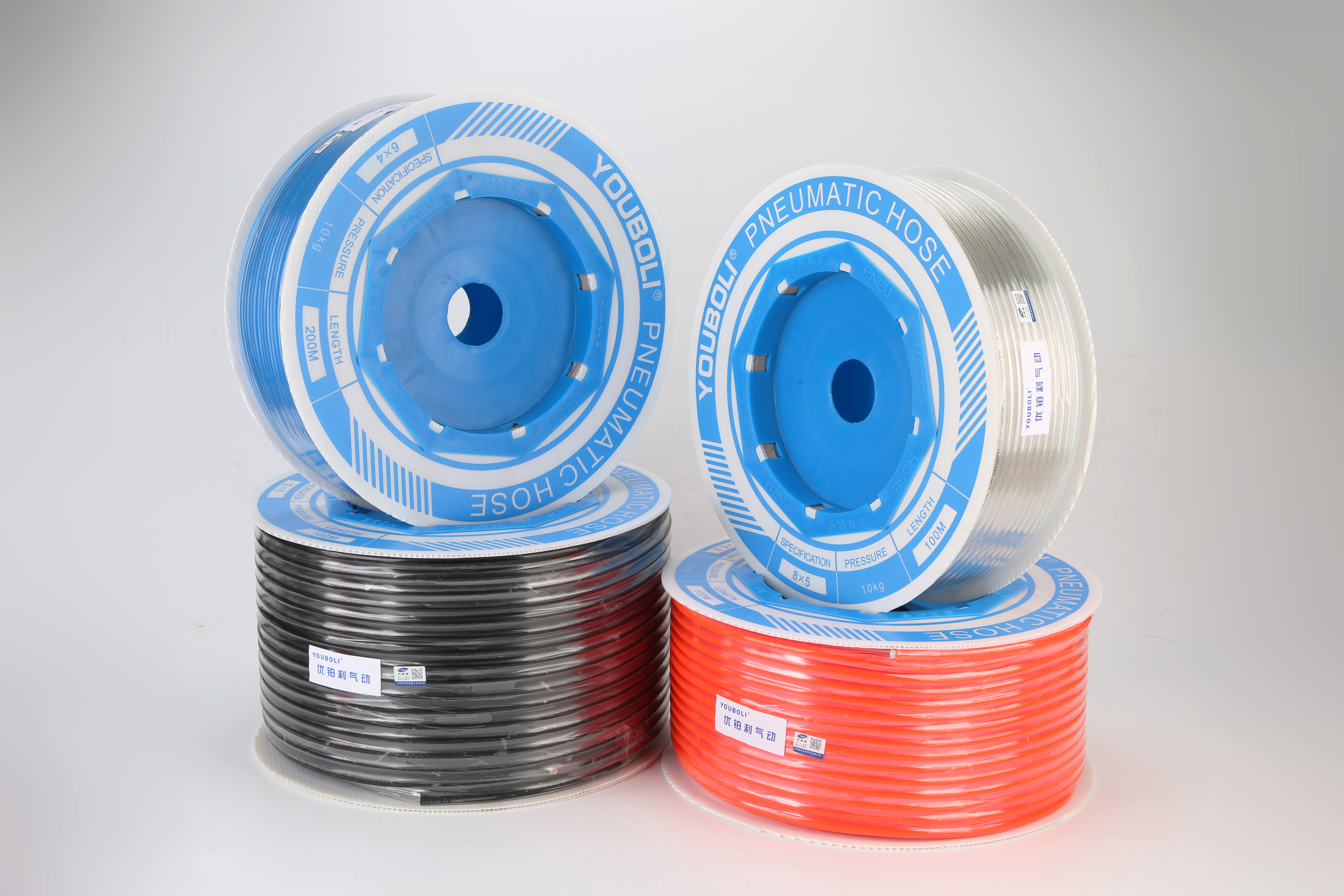

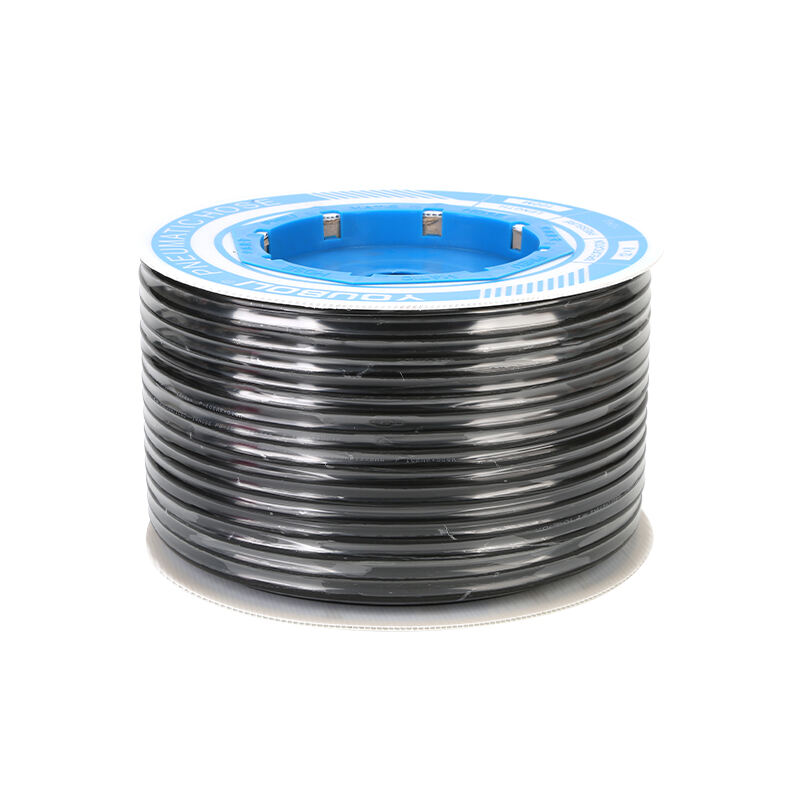

industrial air compressor hose

An industrial air compressor hose is a vital component in pneumatic systems, engineered to deliver compressed air efficiently and safely across various industrial applications. These specialized hoses are constructed with multiple layers of high-strength materials, typically featuring an inner tube made from durable synthetic rubber or thermoplastic, reinforced with high-tensile wire or textile braiding, and protected by an outer cover resistant to abrasion, weather, and chemicals. Designed to withstand high pressures ranging from 150 to 300 PSI or more, these hoses ensure reliable air transmission while maintaining flexibility for ease of use. The construction prioritizes safety with burst-resistant features and secure end fittings that prevent accidental disconnection during operation. Modern industrial air compressor hoses incorporate advanced materials that resist kinking, crushing, and UV damage, ensuring longevity in demanding industrial environments. They serve critical roles in manufacturing, construction, automotive repair, and other industrial sectors where compressed air powers tools and equipment. The hoses are available in various lengths and diameters to accommodate different flow requirements and workspace configurations, making them versatile solutions for diverse industrial needs.