push fit air pipe connectors

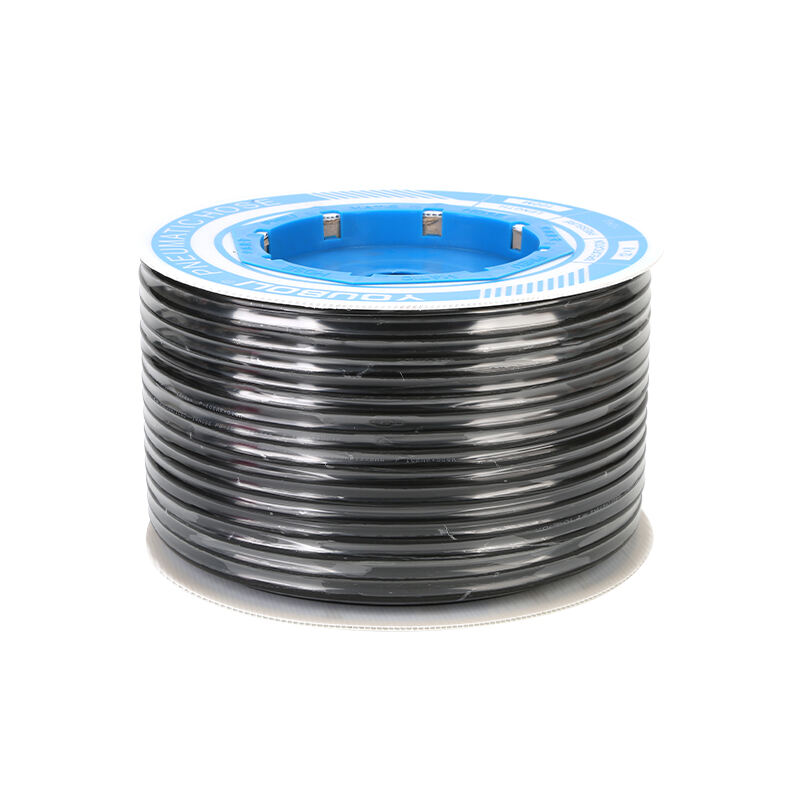

Push fit air pipe connectors represent a revolutionary advancement in compressed air systems, offering a seamless and efficient solution for connecting pneumatic lines. These innovative connectors utilize a sophisticated push-to-connect mechanism that eliminates the need for traditional threading or complex installation tools. The design incorporates a specialized grip ring that automatically secures the tube when inserted, while an internal O-ring creates an airtight seal, ensuring optimal performance and preventing leaks. These connectors are engineered to handle various pressure ranges and are compatible with multiple tube materials, including nylon, polyurethane, and polyethylene. The versatility of push fit connectors makes them ideal for numerous applications across industrial automation, manufacturing processes, and pneumatic systems. Their construction typically features high-grade engineered polymers and corrosion-resistant materials, ensuring durability and longevity in demanding environments. The technology behind these connectors allows for quick installation and removal, significantly reducing maintenance time and improving system efficiency. These connectors are available in various configurations, including straight, elbow, tee, and cross shapes, accommodating different installation requirements and space constraints.