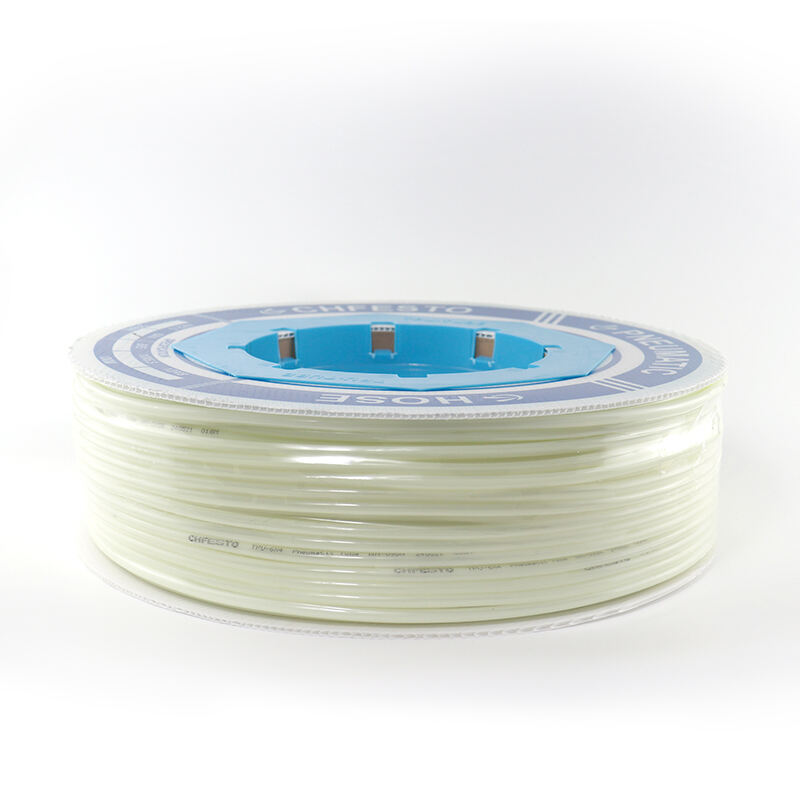

pneumatic connector

A pneumatic connector serves as a crucial component in pneumatic systems, facilitating the secure and efficient connection of air lines and components. These precision-engineered devices ensure airtight seals while enabling quick connection and disconnection of pneumatic lines. Modern pneumatic connectors incorporate advanced features such as push-to-connect technology, self-sealing mechanisms, and corrosion-resistant materials. They come in various configurations, including straight, elbow, and T-shaped designs, to accommodate different installation requirements. The connectors typically feature specialized O-rings and seals that maintain pressure integrity even under demanding conditions. Industry-standard sizes and threading options ensure compatibility across different manufacturers equipment. These connectors play a vital role in maintaining system efficiency by minimizing air leakage and pressure drops. They are designed to withstand various operating pressures and temperatures, making them suitable for diverse industrial applications. The integration of safety features, such as positive locking mechanisms and visual connection indicators, helps prevent accidental disconnections and system failures. Advanced materials like nickel-plated brass and engineered polymers enhance durability and chemical resistance. These connectors are essential in automotive manufacturing, food processing, pharmaceutical production, and general industrial automation applications.