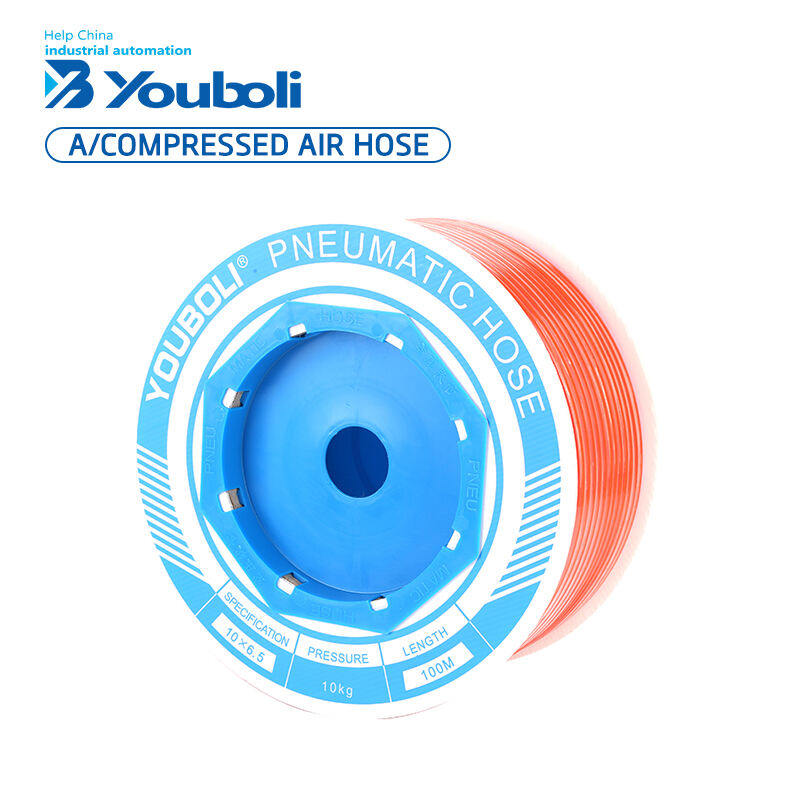

pu pipe fittings

PU pipe fittings represent a revolutionary advancement in fluid handling systems, combining durability with versatility in modern industrial applications. These fittings, crafted from high-quality polyurethane materials, offer exceptional resistance to wear, abrasion, and chemical exposure while maintaining structural integrity under various operating conditions. The innovative design incorporates precision engineering that ensures seamless connections and optimal flow characteristics, making them ideal for both pneumatic and hydraulic systems. The fittings feature a unique molecular structure that provides outstanding flexibility without compromising strength, allowing for reliable performance in both high-pressure and vacuum applications. Their superior shock-absorbing properties help reduce system vibration and noise, contributing to extended equipment life and improved workplace safety. Additionally, the fittings resist microbial growth and feature smooth interior surfaces that minimize flow resistance and prevent material buildup, ensuring consistent performance over time. These components are engineered to maintain their dimensional stability across a wide temperature range, making them suitable for diverse industrial environments, from food processing to chemical manufacturing.