pneumatic tools

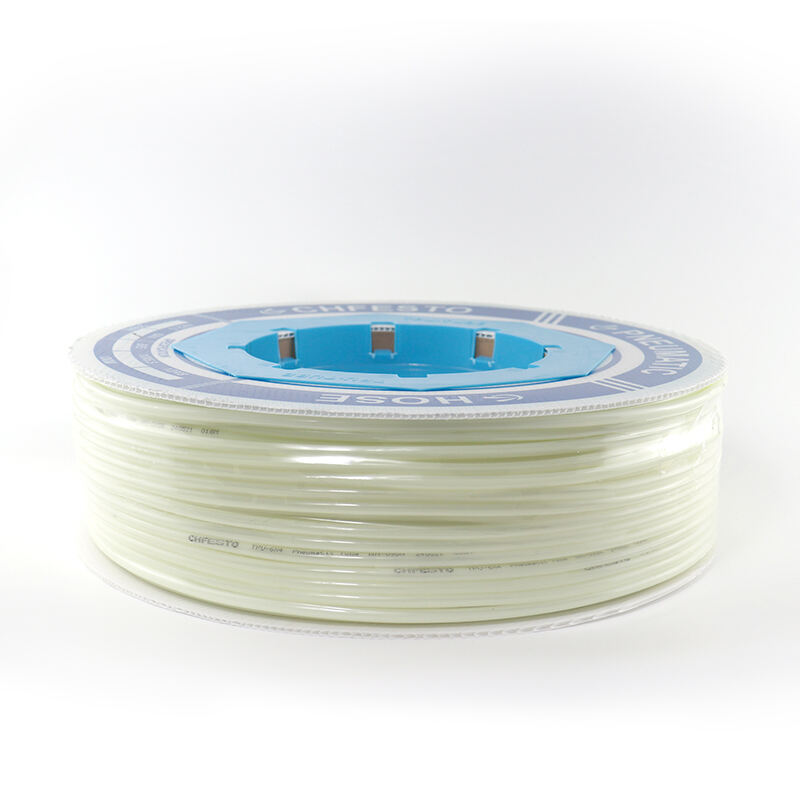

Pneumatic tools represent a cornerstone of modern industrial and construction operations, harnessing the power of compressed air to deliver exceptional performance and reliability. These versatile implements operate through a sophisticated system of compressed air delivery, converting air pressure into mechanical energy to perform various tasks. The technology behind pneumatic tools involves a complex network of components, including air compressors, pressure regulators, and precision-engineered actuators, all working in harmony to provide consistent power output. These tools find extensive applications across diverse sectors, from automotive assembly lines to construction sites. Their fundamental design allows for both heavy-duty industrial applications and precise, controlled operations in more delicate settings. Modern pneumatic tools incorporate advanced features such as adjustable pressure controls, ergonomic designs, and specialized attachments that enhance their versatility. The range includes impact wrenches, drills, sanders, grinders, and numerous specialized implements, each engineered to meet specific operational requirements. Their robust construction ensures longevity, while innovative air flow systems maximize efficiency and minimize energy consumption. These tools have become indispensable in professional settings, offering solutions for tasks ranging from basic fastening operations to complex industrial processes.